History

1947

1990

2006

In 1947 three technicians who specialised in mechanical construction, supported by “Thome industrial“ which was well known for steel forging and casting started the production of trailer axles. The new company called Societé Ardennaise d’Essieux (SAE) grew rapidly thanks to the Thome group’s introduction to the heavy industry and the innovation of the three technicians. Over the years SAE became a leader in the production of road axles in the French market took an important position in the whole European market, thanks to a reliable and efficient products, both from the technical and quality point of view.

In the ‘90s SAE had become a recognised company and partnered with the German group Gigant, which specialised in the production of mechanical and pneumatic suspension. This enables SAE to provide the assembly of axles and complete suspensions to all its customers. In the following years the company specialises in the supply of axles and suspensions for bespoke trailers, low load trailers, tankers, dumpers and forestry trailer, developing drum brakes, disc brakes, suspensions and steering axles for these types of vehicles.

The company with its integration into the group ADR is ready to face new challenges with investment in production, research and development and is aiming to recover its leading position in the market.

2013

2016

2018

SMB was established in the 70’s, specialising in assembly, then expanding for the production of axles and suspensions for all trailers of the group Fruehauf, Titan etc. This supplied all the companies of the Fruehauf group in Europe, Africa, Japan. In 2006, the two companies, SAE and SMB combined to establish a great centre for the manufacture of axles and suspensions reaching the maximum production of 50.000 axles during the 2008, with a turnover of 90,000.000 €.

SAE-SMB India is one of the ADR Group’s important sister companies. Started in 2016 and located in Pune (Maharashtra). The company focus is to sell axles, suspension, spares and component parts of industrial trailers in India and Middle Eastern markets.

SAE-SMB opened an office in the UAE in 2018. SAE-SMB Middle East DWC, located in Dubai World Central, it offers a personalised customer and support service to GCC countries, with a focus on the price/quality/delivery/service ratio for better competitiveness. Experience, flexibility, adaptability and client feedback allow the company to fulfil most of the requirements expected by the different markets whilst always promoting and being proud of French design and technology.

2019

SAE-SMB China is the latest division of the ADR Group. Located in Qingdao, it has approximately 20.000 square metres for production that will range from component parts to finished products. There are two distinct objectives: Export to Asia pacific and development of the internal Chinese market.

Products

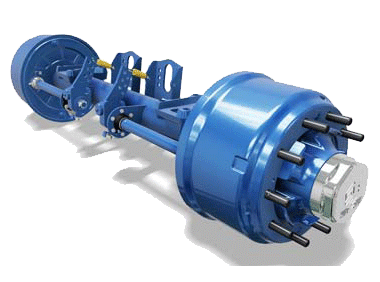

Axles - Drum Brake

Drum brakes are part of the history of the vehicles and road transport. Easily adaptable to every construction requirement, performing high braking in small wheels and adverse environmental conditions, for smooth, highly sensitive braking.

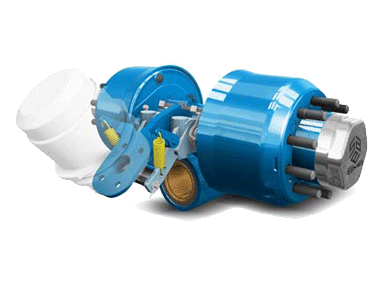

Axles - Disc Brake

The future of transport over long distances is the disc brake. Disc brakes are low fading affected, ensuring maximum efficiency, even at high temperatures; high braking comfort and fast reaction. The compact construction, combined with the fitting of offset wheels, allows the construction of wide and more stable trailer chassis, offering the advantage of using the same wheels for tractor and trailer, with only one type of spare wheel. Today, most trucks have disc brakes, therefore, the use of the same type of brake on the trailer gives uniformity in assembly, improving safety and driving comfort.

Steering Axles

Fuel and maintenance of vehicles are an increasing part of the running costs for a transport company. The steering axle greatly improves the performance of trailers and semi-trailers. The motor vehicle is less stressed, and so saves fuel. Steering axles also help to save the tyre wear and tear. Carriers drive more kilometres with a set of tyres and have less downtime. Even recycled tyres can be used with increased safety.

Pendular Axles

Swinging axles are the best solution for heavy duty vehicles on extreme uneven ground. Flexibility through a rigid and stiff structure defines this High- performance product, always ensuring optimum ground contact. This means high operator safety and optimum load distribution in all travel conditions.

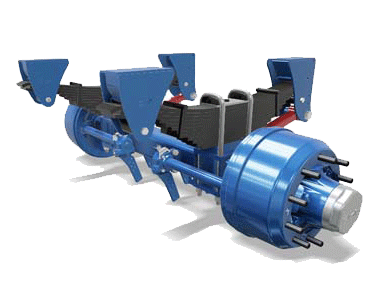

Mechanical Suspensions

Maximum stability

A light structure to carry a heavy load, it’s the requirement for a safe travel. The SAE-SMB leaf spring suspensions optimise flexibility and high resistance under load, comfort and reliability, even for high vehicles.

Perfect alignment of the axles

An effective system of adjustable clamping allows the easy alignment of every single axle thus improving precision in driving, fuel and tyre economy.

High modularity of the components

Most of the components are common to tandem and tridem and allow the creation of suspensions of very different characteristics by replacing only a few components.

Optimization of the braking efficiency of the axles

The SAE-SMB suspensions always allow a high level dynamic compensation of the braking efficiency among the axles, thus ensuring a smooth and equilibrated braking action with optimum distribution of brake wear without any vibration, thanks to the clever position of the camshaft of the drum brakes, which is always in tandem with the wheel rotation.

Silent drive and easy maintenance

All the joints of the suspension are silent-blocs in order to reduce the noise through a simple and easy to maintain construction. No periodic lubrication is necessary so there no risk of malfunction due to rust.

Mechanical Bogie Suspensions

These are heavy duty suspensions, suitable for the extreme uses in quarries and on construction sites for large-scale civil works. Designed for twin wheels and large loads. Capacity of up to 30 tonnes. The short wheelbase makes steering easier. Its compact design optimises the vehicle’s stability.

Pneumatic Suspensions

Air suspension is the most popular on commercial vehicles. Simple construction, modularity and versatility of use, thanks to its large diffusion, they are characterised by the standardised main components, thus improving the availability of spare parts and offering an efficient and responsive service to the users. Compared to traditional mechanical suspensions, pneumatics offer many advantages:

• the vehicle attitude can be adapted to loads and routes

• its self-levelling feature keeps the height of the vehicle constant independently of the load conditions

• can automatically compensate the braking dynamics, always ensuring proper adherence

• can stabilise the vehicle while cornering and integrate ABS and ESP devices to optimise the behaviour of the vehicle

• the modularity of this type of suspension allows to design assemblies with practically unlimited number of axles.

Download the Catalogue

The Group

SAE-SMB Industries - France

Route de Cliron

08090 Ham Les Moines - France

Phone: +33(0)324595454

Fax +33(0)324548158

SAE-SMB Industries - Polska

ul. Bieszczadzka 5

38-540 Zagórz, Poland

Phone: +48 1346 89333

SAE-SMB Middle East DWC - LLC

PO Box 390667

Dubai, U.A.E.

Phone: +971 (0)56 442 6163

SAE-SMB Industries - India

Plot No-I-10, Khed City Industrial Park City, DTA, Village-Kanhersar , Rajguru Nagar, Pune

410505, Maharashtra, India

Phone: +91 8806 078698

SAE-SMB Industries - China

Lingang Road No.2468 - Huangdao District

266400 Qingdao City, Shandong Province

Phone: +86 532 86196636

SAE-SMB Industries - Brasil

Rua Nelson Colela, 105

Distrito Empresarial Prefeito Luiz Roberto Jábali

Ribeirão Preto - SP 14072-068, Brasil

Phone: Tel. +55 16 36173079 - +55 16 39653946